Characteristics:

1. Adopting a dedicated 32-bit motor control chip

2. Closed-loop vector control technology

3. Low speed ultra quiet, smooth current, suitable for applications in various scenarios

4. Voltage level 12VDC~48VDC, supports wide voltage input

5. Pulse signal level supports TTL 3.3V \ 5V, and supports common cathode and common anode connections

6. Maximum pulse frequency of control command 250KHz

7. It has protection functions such as overvoltage, undervoltage, overcurrent, and overtemperature

8. Built in smooth micro subdivision technology

9. When the motor is stationary, the current automatically decays, reducing the amount of heat generated

10. Ultra high cost-effectiveness, economically efficient

11. Acceptable customization

Typical applications:

Widely used in various small and medium-sized automation equipment and instruments, such as electronic processing equipment, 3C non-standard automation equipment, screw locking machines, wire stripping machines, winding machines, terminal machines, laser machines, marking machines, spray painting machines, small and medium-sized carving machines, automatic grabbing equipment, specialized CNC machine tools, packaging equipment and robots.

Product Overview:

Adopting 32-bit ARM digital processing technology and built-in micro and intermediate frequency vibration suppression technology, effectively improving the smoothness of motor operation and reducing heat generation. Segmentation and current can be set through dialing, with a simple interface definition, committed to providing customers with a cost-effective all-in-one machine control solution.

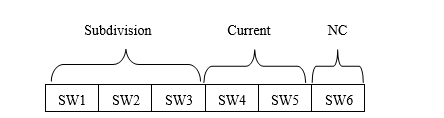

Dial code setting:

Using a 6-digit DIP switch to set the minimum current and fractional value, the detailed description is as follows:

Current | SW4 | SW5 |

0.5A | ON | ON |

1A | OFF | ON |

1.5A | ON | OFF |

2A | OFF | OFF |

Subdivision of dialing codes SW1, SW2, SW3: As shown in the dialing subdivision table below, customers can set the required subdivision through dialing.

Pulse/rev | SW1 | SW2 | SW3 |

400 | ON | ON | ON |

800 | OFF | ON | ON |

1600 | ON | OFF | ON |

3200 | OFF | OFF | ON |

6400 | ON | ON | OFF |

12800 | OFF | ON | OFF |

25600 | ON | OFF | OFF |

51200 | OFF | OFF | OFF |

Control Port (B08B-PASK-1 (LF) (SN) 8-bit Pin)

Pin number | Signal | Function | Explanation |

1 | PU | pulse | Supports 3.3V and 5V levels, using higher levels requires external current limiting resistors |

2 | F/R | direction | Conduction refers to forward rotation, and cutoff refers to reverse rotation |

3 | MF | Enable | Conduction is enabled, cutoff is stopped |

4 | AR | Alarm clear | Conduction can clear fault signals |

5 | XCOM | Input signal common terminal | Supports common anode and common cathode wiring |

6 | ALM | Alarm output | OC gate output |

7 | STA | Motor operating status | High level normal, low level alarm |

8 | YCOM | Output signal common terminal | OC gate output |

Power Port (B06B-XASK-1(LF)(SN) 2-bit pin)

Pin number | Signal | Function Description |

1 | VDD | Power input positive terminal,input voltage 10V~50Vdc |

2 | GND | Power input negative terminal |

Copyright 2023 Copyright Jiangsu Fulling Motor Technology Co., Ltd.